POLYPROPYLENE (PP) - BLUE

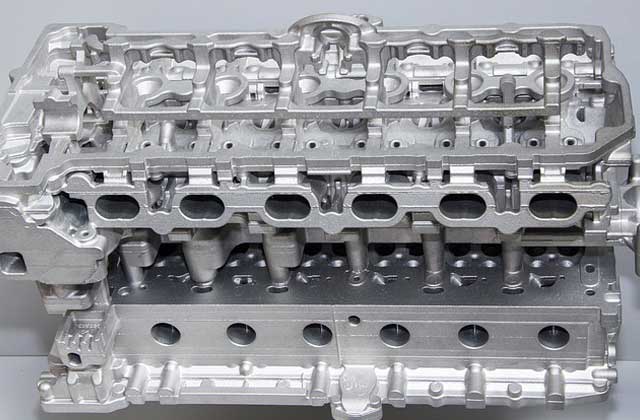

FEATURES | APPLICATIONS | PHOTO PICTURE | ||

100% Recycled Polypropylene | Blow Molding Film Blow Molding Injection Extrusion |

MECHANICAL PROPERTIES | TEST STANDARD | TEST CONDITION | S.I. UNIT | VALUE |

Tensile Strength | GB/T-1040 | 50mm/min | MPa | 17.5-22.0 |

Elongation at Break | GB/T-1040 | 50mm/min | % | 13.5-18.0 |

Izod Notched Impact Strength | GB/T-1043 | 23°C | kJ/m2 | 3.5-5.0 |

OTHERS | ||||

Density | ISO1183-1 | 23°C | g/cm3 | 0.855-0.950 |

Melting Point | ISO11357-3 | 10°C/min | °C | 130 - 200 |

Melt Flow Rate (MFR) | GB/T-3682 | 230°C, 2.16kg | g/10min | 25.5-27.5 |

PROCESSING CONDITION |

Processing Temperature: 180 – 250⁰C |

Remark : However, the actual processing conditions depend on mold design, machine and other environments. |

HANDING & STORAGE |

Handling : Use with adequate ventilation. Avoid dust generation. Avoid contact with eyes and skin. |

Accumulations of dust should be removed from settling areas. |

Storage : Requirements to be met by store rooms and containers |

· This product may react with strong oxidising agents and should not be stored near such materials. |

· Store the bags in areas protected with automatic sprinklers. |

· Storage temperature should be ambient (preferably below 50 °C). |

· Store the product in bags, silo, container, or large cartons to avoid contamination. |